Home ![]() Products

Products ![]() Dryer and Parboiling

Dryer and Parboiling ![]() Dryer

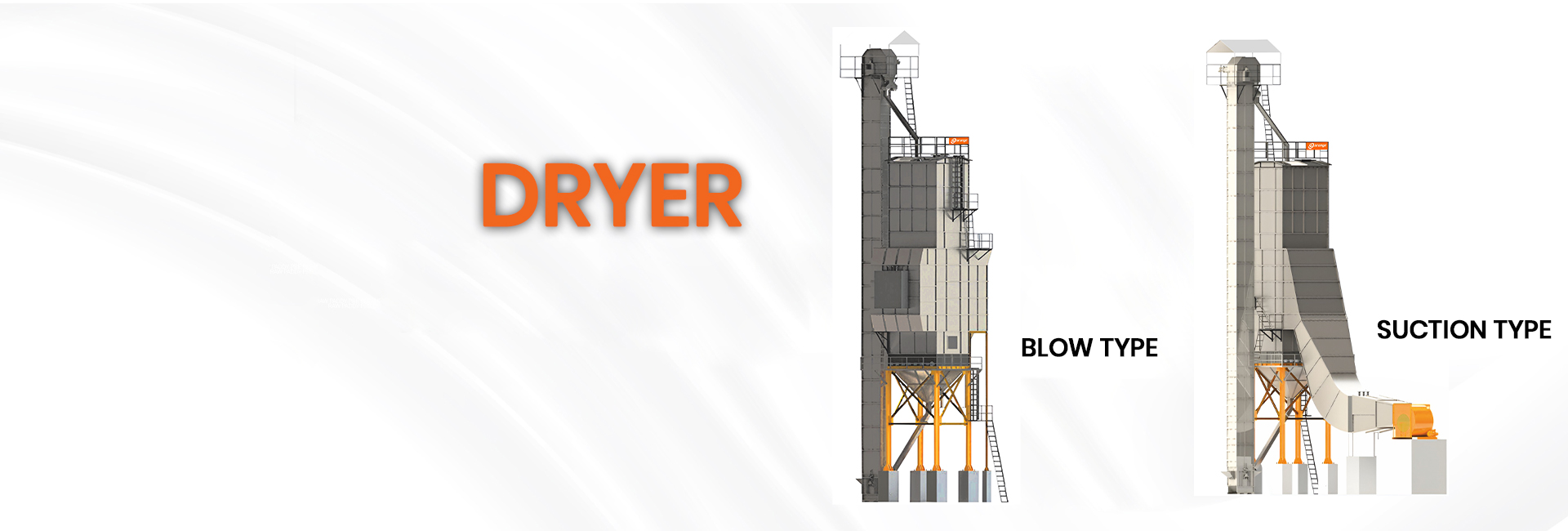

Dryer

Paddy dryer is a specialized machine designed and built to reduce the moisture of paddy. The goal is to produce efficient, safe, and durable drying systems that help farmers with safe storage and help rice millers maintain good grain quality. It works by circulating hot air through the paddy, ensuring uniform drying and minimizing grain damage.

The dryer consists of 3 major parts: V-Ports, responsible for even heat distribution and a homogeneous mixture of paddy; the Feed Roller, which makes the dryer run at a constant speed, ensuring all paddy is dried evenly; and the Heat Exchanger, equipped with an air duct and blower, ensuring high thermal efficiency with less heat energy loss.

Dryers are available in multiple types: Batch type or circulation type dryers and continuous type dryers. Specialized dryers are also designed for RAW paddy. Orange dryers can be supported by 2 major types of heat sources: Steam and Furnace with husk or wood (or husk or wood fuel). The Orange dryer also supports heat sources such as husk or wood furnace and steam systems, and special models are designed for RAW paddy as well.

Orange dryers can also be equipped with 2 major types of heat sources: Steam and Furnace using husk or wood. The Orange dryer can be integrated with husk or wood furnaces and steam systems, and it also has special models designed for RAW paddy.

| Capacity (Tons/No) | 24 | 32 | 40 | 50 | 60 |

|---|---|---|---|---|---|

| Port Box Thickness (mm) | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Storage Box Thickness (mm) | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Port Angle° | 90° | 90° | 90° | 90° | 90° |

| Top 2 layer Port thickness (mm) | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Bottom hopper Thickness (mm) | 3 | 3 | 3 | 3 | 3 |

| Number of Feed Rollers | 8 | 10 | 12 | 14 | 16 |

| Dryer DIMENTION (feet) | 53 | 61 | 57 | 60 | 63 |

| Elevator Cup size (Inches) | 10 | 12 | 12 | 14 | 14 |

| Elevator Capacity (tons) | 28 | 37 | 53 | 53 | 68 |

| Elevator Height (feet) | 74 | 82 | 78 | 81 | 84 |

| Steam Pressure Required (Bar) | 7 ~ 8 | 7 ~ 8 | 7 ~ 8 | 7 ~ 8 | 7 ~ 8 |

| Blower Power (HP) | 15 | 20 | 25 | 30 | 40 |

| Feed Roller Power (HP) | 1.5 | 1.5 x 2 | 1.5 x 2 | 2 x 2 | 2 x 2 |

Grain industry recognition and achieve certification with our comprehensive programs, designed to validate your expertise and enhance your professional standing. Unlock new opportunities and accolades.

Copyright © 2026 Orange Sorting Machines. All Rights Reserved.